Why is the Panama Canal Route for Shipping Imporant?

The Panama Canal route for shipping is one of the most strategically vital waterways in global trade, facilitating the movement of goods between the Atlantic and Pacific Oceans. This 51-mile passage significantly reduces shipping time and costs, making it indispensable for global commerce. Nearly 40% of U.S. maritime traffic relies on the canal, highlighting its importance to the American economy. Recently, political tensions have escalated, with former President Donald Trump raising concerns about Chinese influence over canal operations. As control over trade routes becomes a contested issue, understanding the canal’s historical and economic significance is more crucial than ever.

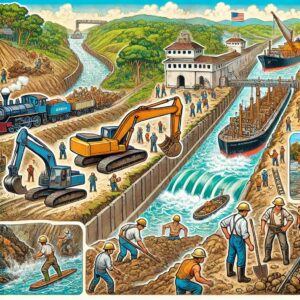

The Construction Challenges of the Panama Canal

The construction of the Panama Canal was an engineering feat plagued by difficulties. Initially attempted by the French in the late 19th century, the project failed due to financial constraints, engineering miscalculations, and rampant diseases like malaria and yellow fever. The United States took over the project in 1904, implementing advanced engineering techniques and a lock-based system that transformed it into one of the greatest engineering triumphs of the 20th century. By 1914, the canal was completed, cutting travel time between the east and west coasts of the Americas and revolutionizing international trade.

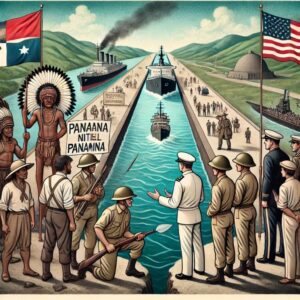

The Shift in Control Over the Panama Canal Route for Shipping

Despite its economic benefits, U.S. control over the Panama Canal route for shipping was met with growing resistance from Panamanians. The Hay–Bunau-Varilla Treaty, which granted the U.S. authority over the canal zone, was signed without Panamanian representation, fueling national resentment. By the 1970s, anti-American sentiment led to negotiations that resulted in the Torrijos–Carter Treaties, ensuring the canal’s transfer to Panama in 1999. These treaties maintained the canal’s neutrality, with the U.S. reserving the right to intervene if national security was threatened. Today, questions arise over whether Panama continues to honor these agreements amidst growing geopolitical tensions.

Rising Concerns Over Chinese Influence in the Panama Canal

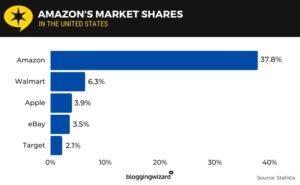

Growing concerns about China’s involvement in Panama have intensified in recent years. Chinese state-backed companies have acquired control over key infrastructure, including ports at both ends of the canal. U.S. officials have accused Panama of favoring Chinese interests and imposing unfair transit fees on American vessels. However, Panama’s recent decision to withdraw from China’s Belt and Road Initiative and audit Chinese-managed infrastructure suggests a shift back toward strengthening ties with the United States. With 70% of canal shipments connected to U.S. trade, Panama’s economic stability remains closely linked to American interests.

The Future of the Panama Canal Route for Shipping

The Panama Canal route for shipping will continue to be a focal point of international trade and geopolitical strategy. As global superpowers vie for influence over critical trade routes, any disruption in canal operations could have far-reaching consequences for the U.S. economy. Agricultural exports, energy shipments, and consumer goods all depend on smooth transit through the canal. While Panama’s recent moves suggest a realignment with U.S. interests, long-term stability remains uncertain. The coming years will determine whether the canal remains a neutral passage or becomes a contested battleground in the evolving landscape of global trade.